Extrusion processes are used in a variety of industries. Extruders are used to form plastic products, such as sealing systems for car bodies. In addition to molding, extruders are also used for chemical processing and modification of materials. The food industry uses this principle to produce artificial meat substitutes, for example. In the plastics industry, this principle is used to produce rubber compounds such as thermoplastic elastomers. In both industries, single or twin screws are often used to feed a material through different zones in the elongated extruder. In the feed section, the materials are heated, compressed, degassed or mixed with other materials.

Overcoming these challenges requires a combination of process optimization, advanced control systems, and continuous monitoring to ensure consistent and high-quality extruded products.

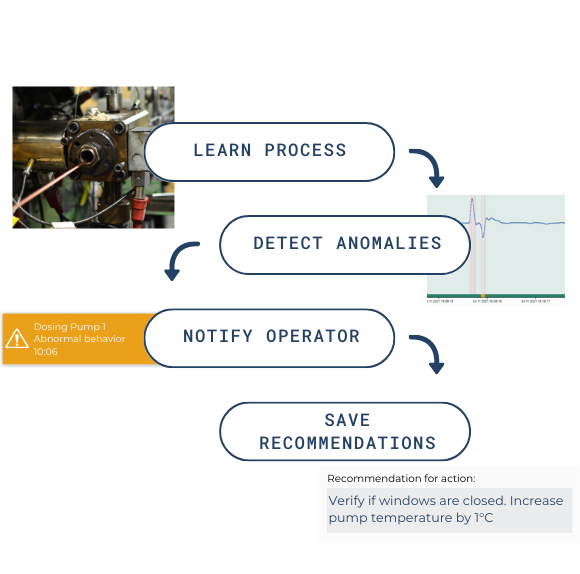

With ExtruAI, we will resolve these challenges. With the help of a scalable assistant, we will give the employee on the extrusion line recommendations on how to readjust the process. This will support the employee's existing knowledge and minimise the number of necessary iterations. The plant operator benefits from less waste and increased machine capacity. Even less experienced employees can regulate the process independently with ExtruAI, which simplifies personnel allocation.

On a technical side, ExtruAI uses a prescriptive Artificial Intelligence, which consists of three components:

Extruders are controlled by PLCs. A PLC can provide data (e.g. sensors, setpoints) via the industry standard for machine communication, OPC UA. The OPC UA standard for data exchange is defined to better align communication between different vendors. EUROMAP standards are defined for extrusion applications. The extrusion standard EUROMAP 83 defines several standard parameters such as troughput, specific output, temperature in different zones, product speed and energy consumption. With the PLC as the OPC UA server and our ExtruAI component as the OPC UA client, the data can be easily collected and automatically analyzed.

The KITT4SME project has developed a managed platform for Kubernetes hosting. We can host our component within this platform.

We want to say thank you to the whole KITT4SME team - here you find the official website.

Here you can find the KITT4SME platform for application hosting and managing.

This work was supported by the H 2020 project "Platform enable KITs of Artificial Intelligence for an Easy Uptake of SMEs (KITT 4 SME)" under GA 952119.

Furthermore, we want to thank HEXPOL Compounding AB for supporting us with data from their manufacturing processes during the project.